STEST (Standart Kontrol ve Test Hizmetleri A.Ş.), savunma, havacılık, otomotiv ve enerji gibi sektörlere yönelik bağımsız test ve belgelendirme hizmetleri sunan, Türkiye'nin en büyük özel test altyapısına sahip firmalarından biridir. Ankara'daki merkezinde EMI/EMC, çevresel, ATP ve otomotiv testleri gerçekleştiren STEST, ulusal ve uluslararası standartlara uygun, güvenilir ve akredite çözümler sunmaktadır.

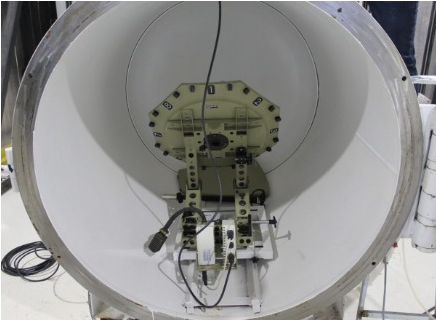

Our Semi-Anechoic EMI/EMC Test Chamber is among Turkey’s most advanced RF EMC facilities, serving military, automotive, and civilian sectors. The 13 x 10 x 9 m chamber features a 6 m diameter turntable with a 70-ton capacity. Tests comply with MIL-STD-461E/F/G standards, including RE101, RE102, RS101, and RS103. TÜRKAK-accredited RS103 tests are conducted from 10 kHz to 40 GHz at 200 V/m and 50 V/m levels. Additional testing is available per ECE R10 and standards for agricultural, construction, and road vehicles. All processes are monitored via a control room equipped with EMC-compliant cameras.

In our Faraday cage/shielded EMI/EMC test room, emission tests (CE101, CE102) and susceptibility tests (CS101, CS114, CS115, CS116, CS118) are conducted in accordance with MIL-STD-461E/F/G standards. Additionally, power system tests are performed in compliance with MIL-STD-704 and MIL-STD-1275. Transient Emission (TE) and Transient Immunity (TI) tests are carried out on vehicle components, primarily in accordance with the ECE R10 standard. Furthermore, our shielded room is equipped to perform tests aligned with civilian standards, including ESD, Radiated Immunity (R.I.), Burst, Surge, Conducted Immunity (C.I.), Magnetic Field, and Power Quality Tests (PQT).

Our Drive-In Environmental Test Chambers are designed to accommodate large-scale products and vehicles, offering testing capabilities in accordance with MIL-STD-810 and other international standards. With chamber sizes ranging from 1 meter up to 21 meters, these units enable high/low temperature, humidity, icing, and solar radiation tests for a wide variety of industrial applications. Ideal for simulating real-world environmental conditions, our chambers provide accurate, reliable results for performance and durability validation.

Within the structure of Standart Kontrol ve Test Hizmetleri A.Ş., Turkey's largest "desert conditions" test chamber enables the simulation of extreme environmental conditions with its dimensions of 12,000 x 12,000 x 6,000 mm. It offers advanced testing capabilities, including temperature variation from +15°C to +71°C, relative humidity between 20% and 50%, wind speeds up to 32 m/s, and high dust and sand concentration. The 10-meter diameter turntable has a load capacity of 70 tons. This system allows for comprehensive dust and sand resistance testing of both military and civilian vehicles.

As Standard Control and Testing Services Inc., we conduct salt spray tests in our salt spray test chamber with dimensions of 1200x1200x600 mm. The durability of protective coatings and surfaces against salt spray is tested in accordance with MIL STD 810, RTCA DO 160, and ISO standards. During the test, samples are exposed to a controlled salt spray environment, followed by physical and electrical inspections and corrosion observations. Any defects identified are meticulously recorded. This process allows us to provide our clients with reliable corrosion resistance reports fully compliant with industry standards.

As Standard Control and Testing Services Inc., we conduct low-pressure (altitude) tests in our 1510x2210 mm low-pressure test chamber. This sealed and thermally insulated chamber is equipped with systems that provide and monitor the required pressure and temperature conditions. During the test, the sample’s performance under low pressure and rapid pressure changes is observed, and any defects are thoroughly recorded. This process allows us to evaluate the durability of materials exposed to low-pressure environments and sudden pressure variations in accordance with industry standards.

As Standard Control and Testing Services Inc., our vibration and shock testing infrastructure consists of advanced vibration test systems with a 50 kN capacity capable of testing along the X, Y, and Z axes. This infrastructure enables comprehensive evaluation of samples against vibration and shock effects encountered in real operating conditions. Tests are conducted in accordance with MIL STD 810, RTCA DO 160, and ISO standards. Controlled frequency, amplitude, and sudden shock pulses are applied to analyze the performance and durability of the samples, with all detected defects meticulously recorded. This allows us to provide our clients with reliable and fully standards-compliant test results.

As Standard Control and Testing Services Inc., we perform rain spray tests in our modern and advanced rain test chambers. These tests verify the resistance of samples to rain and water under real outdoor conditions in accordance with MIL STD 810, RTCA DO 160, and ISO standards. During the test, samples are exposed to controlled water spray at specified pressures and angles. At the end of the test, the performance of the sample is inspected and any waterproofing defects are recorded. This enables us to provide our clients with reliable and fully standards-compliant rain resistance reports.